In manufacturing, rising energy prices often dominate conversations about cost control. Electricity tariffs, carbon-related charges, and fuel volatility are seen as the primary threats to profitability.

But energy is rarely the root cause.

The real cost in manufacturing is unpredictability — in jobs, machines, materials, and resources.

Cost is operational before it is financial

Traditional costing methods focus on financial reporting: overhead allocation, standard costing, variance analysis. These tools are necessary, but they are backward-looking.

Manufacturing cost, however, is created on the shop floor long before it appears in financial statements.

It is shaped by:

- Unplanned machine downtime

- Scrap and rework

- Suboptimal scheduling decisions

- Material shortages

- Idle capacity caused by inaccurate planning

When these variables are unstable, cost escalates — regardless of energy prices.

By the time cost increases are visible in accounting reports, the operational cause has already occurred.

Why lean fails without real-time visibility

Lean methodologies aim to eliminate waste and stabilize production flow. However, lean cannot function without accurate and timely operational data.

Without real-time visibility into:

- Equipment effectiveness (OEE)

- Work-in-progress status

- Scrap rates and quality deviations

- Labor and machine utilization

Lean becomes theoretical.

This is where a manufacturing-first ERP platform such as Epicor Kinetic plays a critical role.

Designed specifically for industrial environments, Epicor Kinetic integrates production, materials, quality, and financial data into a unified model — enabling real-time visibility into cost drivers as they occur.

Manufacturing-centric costing with Epicor Kinetic

Predictability requires more than financial reports. It requires operational integration.

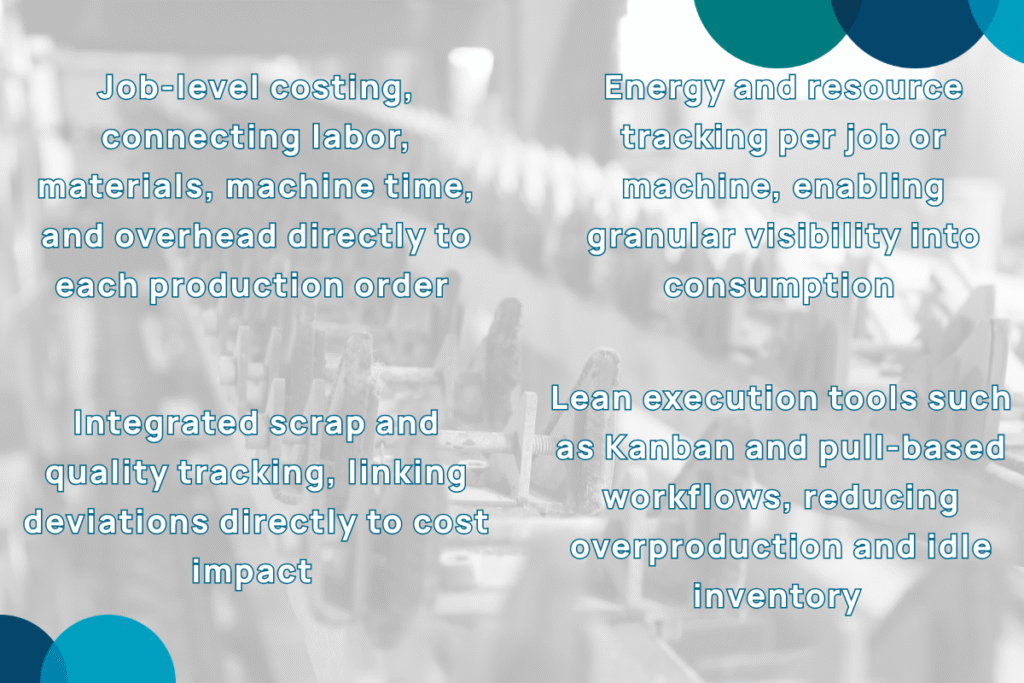

Epicor Kinetic supports:

Because operational events feed directly into the ERP in real time, cost is no longer estimated after the fact — it is measured at the source.

Turning energy from risk into a variable

Energy volatility becomes particularly damaging when production lacks predictability.

With integrated planning and costing in Epicor Kinetic, manufacturers can:

- Shift production phases to lower electricity tariff periods

- Optimize batch sizes to reduce setup time and tooling changes

- Evaluate alternative routing or materials before cost impact escalates

- Analyze energy consumption per job, product, or production line

Energy becomes measurable at the operational level — not just at the utility bill level.

From cost visibility to scenario control

Beyond operational tracking, Epicor Kinetic integrates advanced analytics capabilities, including built-in reporting tools and compatibility with platforms such as Epicor Data Analytics and Grow BI.

This enables manufacturers to:

- Visualize cost per job, product, or customer

- Combine energy consumption, pricing, and equipment performance metrics

- Run what-if simulations on capacity shifts or sourcing changes

- Evaluate investment decisions such as energy-efficient equipment upgrades

When cost, capacity, and performance data coexist within a single system, scenario thinking becomes practical.

Dashboards move from retrospective reporting to proactive decision support.

What this means for manufacturing leaders

Cost optimization is not a financial exercise. It is an operational discipline supported by the right technology foundation.

With a manufacturing-focused ERP such as Epicor Kinetic, leaders gain:

- stable and realistic production planning

- transparent job-level cost visibility

- integrated lean execution tools

- scenario-driven decision support

In a volatile industrial environment, predictability is not just efficiency — it is competitive advantage.