What the G2 Fall 2025 Report reveals for manufacturers

Manufacturers today rarely operate under a single production model. Discrete, process, and engineer-to-order (ETO) workflows increasingly coexist within the same organization, driven by customization, shorter product lifecycles, and volatile demand. This operational reality is precisely why mixed-mode ERP systems have become a strategic requirement rather than a technical upgrade.

Read the full report here

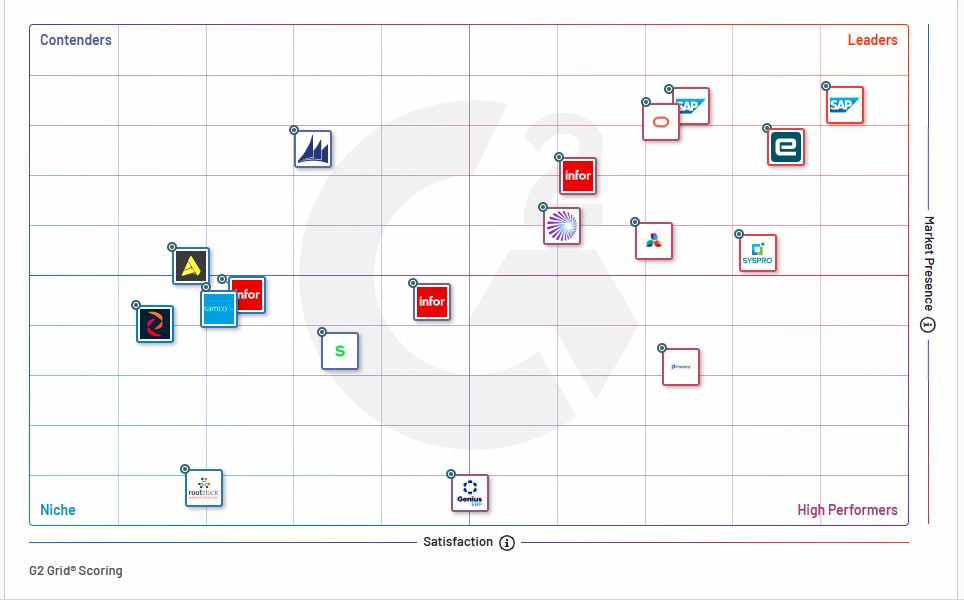

Understanding the G2 Grid®: why Leadership matters

G2’s Grid® methodology evaluates vendors along two critical dimensions:

- Customer Satisfaction, based on real user reviews

- Market Presence, reflecting adoption, scale, and momentum

Only vendors that perform strongly across both axes are positioned in the Leader quadrant. In Fall 2025, Epicor is listed among a select group of ERP platforms that combine high satisfaction with meaningful market adoption in the mixed-mode ERP category.

This matters because mixed-mode ERP is not a generic category. According to G2’s definition, qualifying solutions must support:

- Multiple production methods simultaneously

- Rapid switching between manufacturing modes

- Advanced BOMs, formulas, and product configuration

- Consolidated costing, quality management, and performance tracking across operations

In other words, this is ERP for manufacturers operating at the edge of complexity.

What the data says about Epicor

The Fall 2025 report highlights several performance indicators that explain Epicor’s Leader positioning:

- 213 verified user reviews, one of the highest volumes in the category

- 77% of users rating the solution 4 or 5 stars

- 73% likelihood to recommend, indicating strong peer endorsement

- Consistent scores across core manufacturing capabilities such as MRP, order tracking, and production control.

Beyond raw satisfaction metrics, Epicor demonstrates a strong footprint in mid-market manufacturing, where operational flexibility, faster implementation, and industry fit are often more critical than generic ERP breadth. The report shows that approximately 75% of Epicor users come from mid-sized organizations, underscoring its alignment with manufacturers that need enterprise-grade capabilities without enterprise-level complexity.

Beyond raw satisfaction metrics, Epicor demonstrates a strong footprint in mid-market manufacturing, where operational flexibility, faster implementation, and industry fit are often more critical than generic ERP breadth. The report shows that approximately 75% of Epicor users come from mid-sized organizations, underscoring its alignment with manufacturers that need enterprise-grade capabilities without enterprise-level complexity.

Read the full report here

Mixed-Mode Manufacturing: where Epicor stands out

One of the most telling insights from the G2 data is Epicor’s performance in environments where manufacturing models overlap rather than follow clean lines.

Mixed-mode manufacturers often struggle with:

- MRP logic that fails across hybrid workflows

- disconnected planning between shop floor and supply chain

- limited visibility when ETO, batch, and discrete processes collide

User feedback cited in the report points to Epicor’s strengths in:

- operational visibility, enabling planners and production managers to act on real constraints rather than static plans

- material Requirements Planning (MRP) that adapts across production modes

- order and inventory traceability, critical for compliance and quality control.

These capabilities are not abstract features; they directly address the daily friction manufacturers face when standard ERP assumptions no longer hold.

Adoption and Time-to-Value: a practical indicator

Another important dimension covered by the report is implementation and adoption. According to G2’s aggregated data:

- Epicor projects reach go-live in approximately 8.9 months on average

- 86% average user adoption, significantly above the category average

- A payback period of around 29 months, aligning with realistic ROI expectations for manufacturing ERP investments.

For manufacturing leaders, these numbers matter as much as functionality. ERP success is measured not only by what the system can do, but by how quickly it becomes part of everyday operations.

What this recognition signals to manufacturing leaders

Epicor’s continued placement in the Leader quadrant sends a clear signal to manufacturers evaluating ERP platforms for mixed-mode operations:

- The solution is validated by peers, not analysts alone

- It scales across manufacturing complexity without forcing process compromise

- It balances depth in production with usability and adoption

In a market where ERP decisions directly impact service levels, cost control, and operational resilience, independent recognition like the G2 Grid® provides a valuable reality check.

Looking ahead: ERP as an enabler of manufacturing resilience

The broader takeaway from the Fall 2025 G2 report is that ERP leadership is increasingly defined by flexibility. As manufacturers diversify products, customize orders, and regionalize supply chains, mixed-mode capabilities are becoming the norm rather than the exception.

Epicor’s recognition reflects a strategic focus on manufacturing-first ERP design—one that aligns systems with how factories actually operate today, not how they operated a decade ago.

For organizations navigating hybrid production models, this distinction can make the difference between an ERP that merely records transactions and one that actively supports smarter, faster decisions on the shop floor.

ATC as an Epicor Authorized Partner

As Epicor’s Authorized Partner and the Exclusive Distributor of Epicor Kinetic Solutions in Greece and Cyprus since 2001, we believe that this recognition validates our ability to provide manufacturers with the best ERP solutions.