In modern manufacturing, the greatest operational risk is unplanned downtime. A single failure in a critical machine can stop an entire production line, disrupt precision machining, and delay whole projects – especially in sectors like defense manufacturing, where delivery schedules are tightly controlled and deviations are not an option.

To gain a decisive competitive edge, manufacturers must transition to “smart factory” models, where decisions are driven by real-time data. This transformation stands on two key pillars: MES systems and predictive maintenance.

The Data Foundation: MES and IoT

A Manufacturing Execution System (MES) acts as the control center of the shop floor. Its role is to digitize production processes and collect all operational data in real time, giving manufacturers full visibility into what’s happening — as it happens.

How is data collected?

1. Historical and Operational Data (Data Collection)

The MES records all critical information in a unified database: production speed, cycle times, errors, machine stops, utilization metrics, quality control checks, and maintenance/service conditions. No more paper logs or scattered Excel files – just clean, consistent data ready for analysis.

2. Real-Time Data (IoT Sensors)

Modern factories equip critical machines with IoT sensors measuring key parameters such as vibration, temperature, and pressure. These readings flow directly into the MES and ERP, ensuring end-to-end visibility across the entire digital thread.

Turning Measurements Into Predictions (AI/ML)

Raw data alone cannot prevent costly interruption. To avoid breakdowns before they occur, sensor reading must be transformed into predictive insights.

This is where analytics platforms and Machine Learning (ML) come into play:

- Sensor data is transmitted from the MES to specialized analytics tools.

- Predictive maintenance solutions apply AI/ML algorithms to interpret these detailed measurements.

- The algorithms identify patterns and anomalies that typically precede a failure — for example, a subtle but persistent increase in vibration.

When a deviation is detected, the MES triggers an alert and schedules maintenance proactively. This ensures machines are serviced exactly when needed — before they fail.

Predictive maintenance is one of the most impactful use cases of MES, especially when the system also functions as a Digital Twin of the production environment.

AI/ML components that transform data into actionable predictions are often developed or delivered by specialized teams — such as ATC’s applied AI teams — ensuring maximum performance and reliability.

The Results: Cost Savings and Higher Reliability

Being able to anticipate failures rather than react to them leads to clear, measurable outcomes:

- Extended equipment lifespan, improving overall production reliability

In practical terms, this means your factory stays up and running.

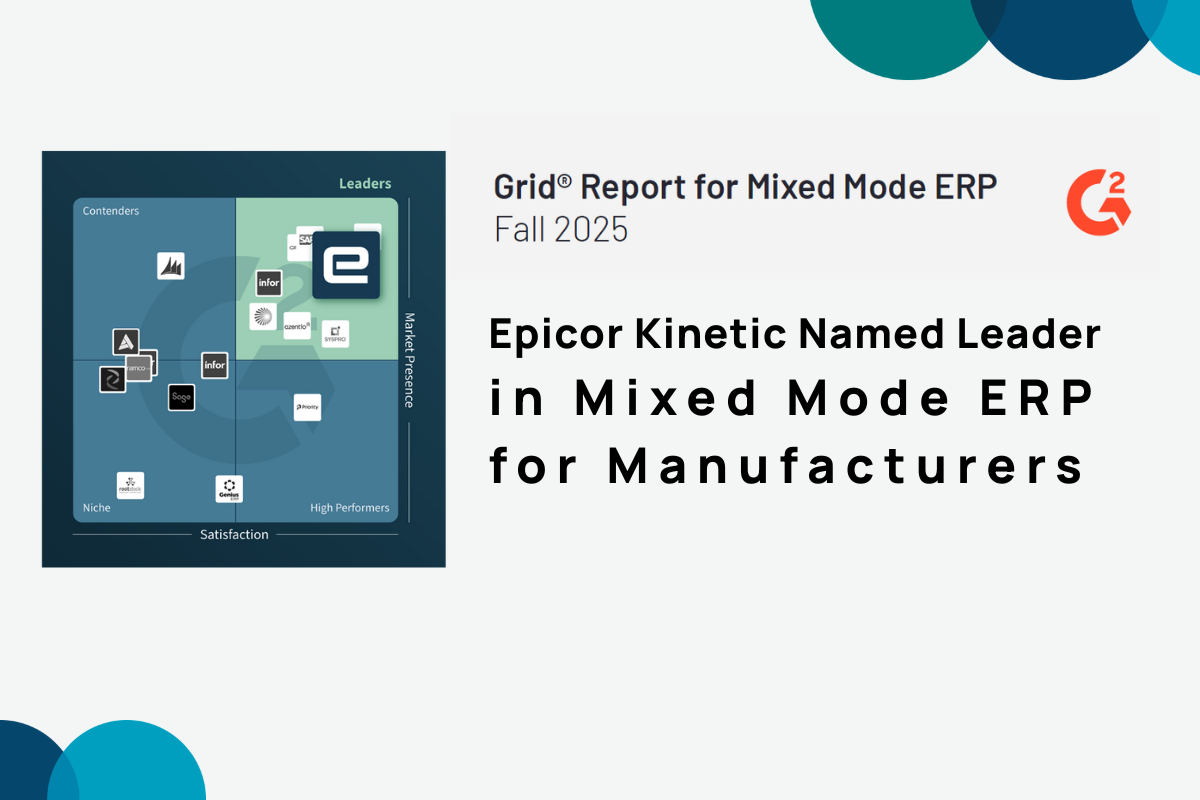

For example, manufacturers using solutions such as Epicor Kinetic — which includes an integrated MES — have reported a 34% increase in production capacity and 12% improvement in equipment utilization.

MES & ERP: The Platform Behind a Data-Driven Factory

To unlock these benefits, the MES must operate in full synchronization with the ERP. Together, they create a unified source of truth for the entire business.

An integrated MES–ERP environment enables:

- Real-time monitoring of production lines

- Better resource and equipment allocation

- Faster, evidence-based decision-making

- A seamless digital workflow from planning to execution

Transitioning to a data-driven factory is not simply a technical upgrade.

It is a strategic shift that turns everyday measurements into predictive power, maximizing performance while minimizing risk.

Want your ERP and MES to function as a truly data-driven platform that keeps your operations running without interruptions?

Check also