In the rapidly evolving landscape of smart factory initiatives and digital transformation, manufacturers are constantly seeking the next competitive edge. While the focus often falls on advanced robotics, IoT sensors, and Artificial Intelligence, the most foundational and often overlooked step is the simplest: eliminating paper from the shop floor.

Going paperless is not merely an administrative task or an environmental initiative; it is a strategic imperative that lays the essential groundwork for a truly connected, data-driven manufacturing operation. In the era of Industry 4.0, relying on paper-based processes is no longer just outdated—it is a significant competitive liability and a measurable business risk.

The hidden costs: why paper is a Smart Factory liability

The transition to a paperless manufacturing environment represents a fundamental shift in operational philosophy. It moves beyond simply converting paper forms into digital documents (a “PDF of a form” is not paperless) to a complete, real-time digitization of all shop-floor processes, including work orders, quality checklists, maintenance logs, and Bills of Materials (BOMs).

The continued reliance on paper introduces a cascade of hidden costs and inefficiencies that actively undermine the goals of digital transformation.

- Data inaccuracy and human error

Paper-based systems are inherently prone to error. Manual transcription of data from a machine or process onto a physical form introduces opportunities for mistakes, illegible handwriting, and data loss. This flawed data then feeds into critical systems, leading to scrap, rework, and incorrect production decisions. Research indicates that the process of manual data entry can be reduced by 50% to 85% through digitization, directly addressing this core issue. - Lack of real-time visibility

In a paper-driven environment, data is recorded later—at the end of a shift, or when a supervisor collects the forms. This delay creates a critical blind spot for management and planning systems. By the time the data is entered, processed, and analyzed, the opportunity to intervene and correct a problem has often passed. A Smart Factory demands real-time information to enable immediate, proactive decision-making. - Outdated information and version control

Workers on the shop floor often waste up to 20% of their time searching for or verifying the correct version of a Standard Operating Procedure (SOP) or work instruction. Furthermore, the lack of a centralized system means that work instruction standards are difficult to achieve, with different teams using various unintegrated software (Word, Excel, PowerPoint). If a critical engineering change is made, the paper-based system requires printing, distribution, and manual verification that the old version has been removed—a process that is slow, error-prone, and a major source of non-conformance. Digital systems ensure that operators always see the single, most up-to-date version of any document or instruction. - Missing feedback loops and lost tribal knowledge

Paper-based processes rarely include a formal mechanism for operators to report deficiencies or suggest improvements to work instructions. This missing feedback loop limits the ability to retain valuable “tribal knowledge” and prevents continuous process improvement. Digital systems, conversely, incorporate operator feedback directly at the station level, capturing and preserving this critical knowledge within the system for future use. - Limited traceability and compliance risk

For manufacturers operating under strict regulatory requirements, paper records become “data black holes” during audits. Locating, verifying, and presenting a complete audit trail across thousands of physical documents is time-consuming and costly. A digital system provides instant, timestamped, and unalterable records, ensuring complete traceability and simplifying compliance. - Environmental and physical costs

Beyond the direct operational risks, paper processes carry a significant environmental footprint, which is increasingly relevant in today’s focus on Environmental, Social, and Governance (ESG) factors. The manufacturing of paper consumes vast amounts of water and energy, and the sheer volume of paper used on a factory floor—often estimated at thousands of sheets per employee per year—translates to a measurable negative impact. Furthermore, the physical storage of years of compliance and production records consumes valuable factory real estate and adds administrative overhead for retrieval and disposal. Going paperless is a clear step toward a more sustainable and physically efficient operation.

Paperless: the foundation of the Smart Factory

The true value of going paperless is realized when it is viewed as the essential first step in a broader digital strategy. The digital data captured on the shop floor is the lifeblood of the smart factory, and it is the integrated ERP and MES systems that act as the central nervous system.

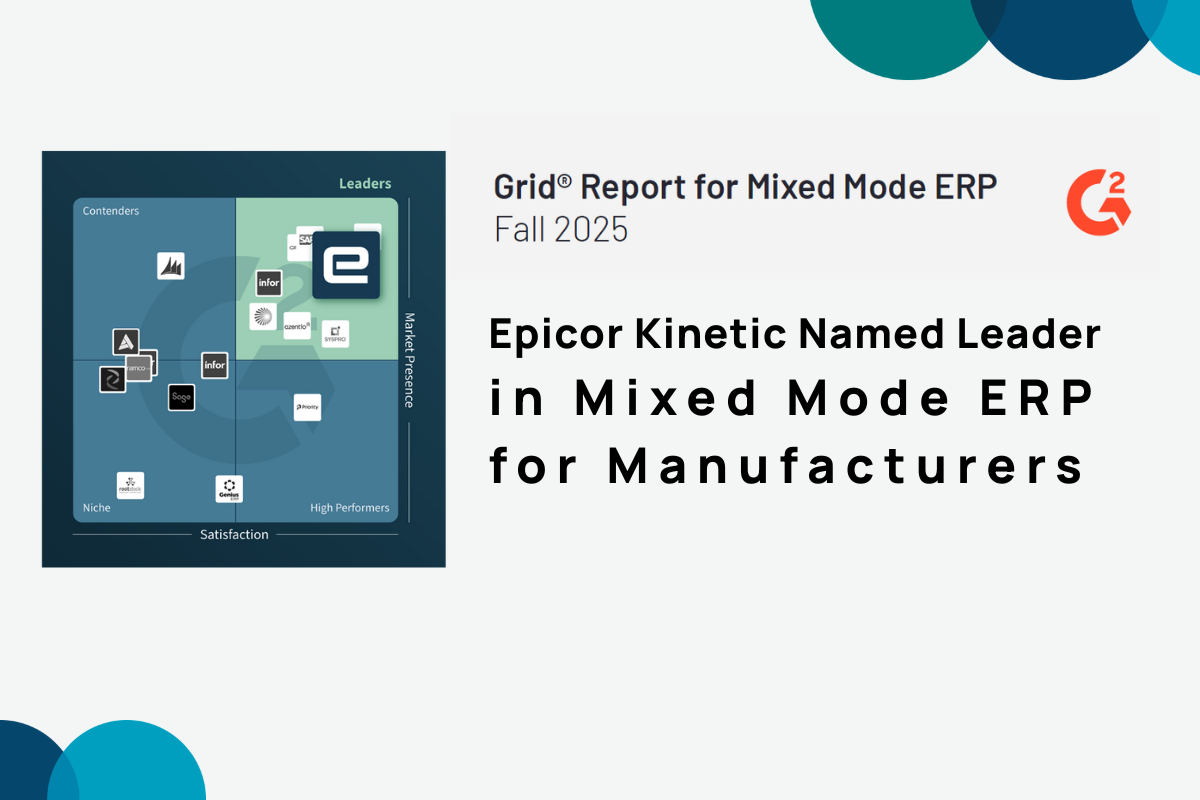

A modern, integrated ERP platform like Epicor Kinetic is designed to be the digital core of this paperless operation. It is not simply a “back office” system; it extends its reach directly to the point of production, transforming the operator’s workstation into a connected, data-capture hub.

The Epicor Kinetic advantage

Epicor’s strategy for empowering digitalization, particularly for small and medium manufacturers, centers on creating a seamless flow of information from the machine to the enterprise. The paperless approach is the critical human-interface layer that completes this loop:

- Digital Work Instructions: Operators receive work orders, visual aids, videos, and quality checks directly on a tablet or terminal. This eliminates the need for printed travelers and ensures the operator has exactly what they need, when they need it.

- Real-time data capture: Data is captured instantly at the source, either automatically via machine interfaces or through guided, standardized digital forms completed by the operator. This instant data feed provides the real-time visibility necessary for calculating metrics like Overall Equipment Effectiveness (OEE).

- End-to-end integration: By tightly integrating the MES with the ERP, the system ensures that every action on the shop floor—from starting a job to recording a quality check—immediately updates the enterprise-level planning, inventory, and scheduling systems. This eliminates the “lag” that cripples paper-based operations.

This unified approach ensures that the investment in digitalization is not fragmented. The paperless shop floor becomes the engine that drives the ERP’s intelligence, enabling predictive maintenance, dynamic scheduling, and true data-driven decision-making.

The shift also fundamentally changes the operator’s role. Instead of being a manual data collector, the operator becomes a data user, empowered with all necessary information—from visual work instructions and 3D models to real-time quality feedback—delivered directly to their terminal. This empowerment leads to higher job satisfaction, faster training, and a significant reduction in the time spent on non-value-added tasks, directly translating to improved labor productivity and a higher OEE. The paperless system is the critical link that transforms raw machine data into actionable insights for the human workforce.

Maximizing quality with advanced digital instructions

The true power of an integrated solution like Epicor Kinetic lies in its ability to implement advanced, error-proofing concepts:

- Smart work instructions: These instructions automatically react to model and component variations, ensuring the operator only sees the correct steps for the specific product being built. They can also tailor the level of detail based on the operator’s experience level, providing full guidance for new hires and simplified steps for veterans.

- Event-based work instructions: By integrating with quality checks, the system can automatically display a specific corrective action instruction if a part is rejected, eliminating guesswork and ensuring immediate process control.

- Animated guidance: Visual guidance, such as animations highlighting the next step or component, provides faster learning potential and reduces the chance of assembly errors.

The quantifiable return on investment (RoI)

The most compelling argument for adopting paperless manufacturing is the significant, quantifiable return on investment (RoI) it delivers. This is not a theoretical benefit; it is a proven outcome for manufacturers who have successfully integrated their shop floor with their enterprise systems. By eliminating the inefficiencies of paper and leveraging the power of real-time data, manufacturers see dramatic improvements across key operational metrics that directly impact the bottom line.

The financial case for going paperless is built on a foundation of hard data, sourced from a combination of industry benchmarks, independent research, and the proven results of successful Epicor client case studies. These metrics demonstrate a clear path to achieving a strong RoI from your digital transformation investment.

The following figures, compiled from various industry benchmarks and reports, illustrate the potential impact of a successful paperless and digital transformation initiative:

| Key Performance Indicator (KPI) | Potential Improvement | Operational Impact |

| Work instruction efficiency | Up to 75% to 80% savings | Direct, from eliminating manual processes for creation, distribution, and updating of instructions |

| Productivity & throughput | Up to 50% increase in data processing capacity; 10-30% increase in throughput | Faster order fulfillment, increased capacity without capital expenditure |

| Labor productivity | 15-30% improvement | Operators focus on value-added tasks, reducing non-productive time spent on administration |

| Data entry time reduction | 50-85% reduction | Significant reduction in administrative overhead and associated labor costs |

| Defect & rework reduction | 30-40% reduction | Lower scrap rates, improved quality control, and reduced cost of non-conformance |

| Operational cost savings | Up to 9K annual savings per team member | Direct savings from paper, printing, storage, and reduced time spent on manual processes |

| Production Gains | 20% for early adopters | Overall efficiency boost from leveraging real-time data and connected systems |

These metrics demonstrate that the financial benefits of going paperless extend far beyond simple savings on paper and ink. The real ROI is found in the operational agility, the reduction of risk, and the enhanced ability to compete in a global market that demands speed and precision. The combined effect of improved throughput, reduced defects, and higher labor productivity creates a compounding return that accelerates the overall digital transformation journey. This holistic view of ROI—where the elimination of paper is the catalyst for enterprise-wide efficiency—is the true business case for paperless manufacturing.

The time for paperless is now

The question for manufacturers today is no longer whether to embrace digitalization, but how quickly and effectively they can execute the transition. Paperless manufacturing is the critical first step, transforming the chaotic, error-prone shop floor into a clean, connected, and intelligent data source.

By leveraging an integrated platform like Epicor Kinetic, manufacturers can ensure that their paperless initiative is not a standalone project, but a seamless component of their larger Smart Factory journey. This approach provides the foundation for superior data accuracy, real-time visibility, and the operational excellence required to thrive in the modern industrial economy.

The transition is an investment in future competitiveness. The time to move from paper-based liability to digital asset is now.

Disclaimer: The percentages provided are indicative and based on industry benchmarks and Epicor client case studies. Results may vary depending on the processes and environment of each business.